About us

Dryden Aqua is one of the largest manufacturer of glass filtration media. As marine biologists, we have a unique knowledge combination and detailed understanding of the biological as well as the physio-chemical reactions in water. This has enabled us to develop and manufacture a highly innovative range of products such as the Activated Filter Media AFM®.

We are proud to provide sustainable and cost-effective solutions for the drinking & waste water industry, for aquaria and aquatic life support systems as well as for swimming pools worldwide.

About Dr. Howard Dryden

Dr. Howard Dryden is the founder of Dryden Aqua Ltd and a marine biologist from Edinburgh. The company was founded from his PhD research on molecular sieve ion exchange zeolitic sand filtration systems for closed system aquaculture, and development of intensive aquaculture technology.

Dr. Dryden has unique knowledge combination of biology, chemistry and technology and is the inventor of the activated, bio-resistant filter media AFM®. Dr. Dryden is one of the world’s leading experts in sustainable water treatment.

our mission

Our mission is to provide solutions that have a positive environmental impact on our ecosystem. We help to make this world a better place: a non-toxic environment for everyone.

SAVE THE OCEANS

SAVE THE PLANET

Dryden Aqua supports GOES Foundation to save coral reefs and restore plankton levels in our oceans.

the team that drives our mission

Dominik Graf

Philipp Meyer

Mike Causer

Florent Thevenin

Jonathan Sollberger

Jamie McBride

Jochen Kallenberg

Mike de Maine

Jakob Surber

Jimmy Lamb

Matthew Dryden

Dominik Schnyder

Nicole Ryf

Anna Blunschi

André Schmid

Eleanor Jervis

Terry Chang

Karen McIntyre

Agnieszka Szewczyk

Patrycja Nawrocka

Norbert Miernik

Yvonne B. Graf-Cathomen

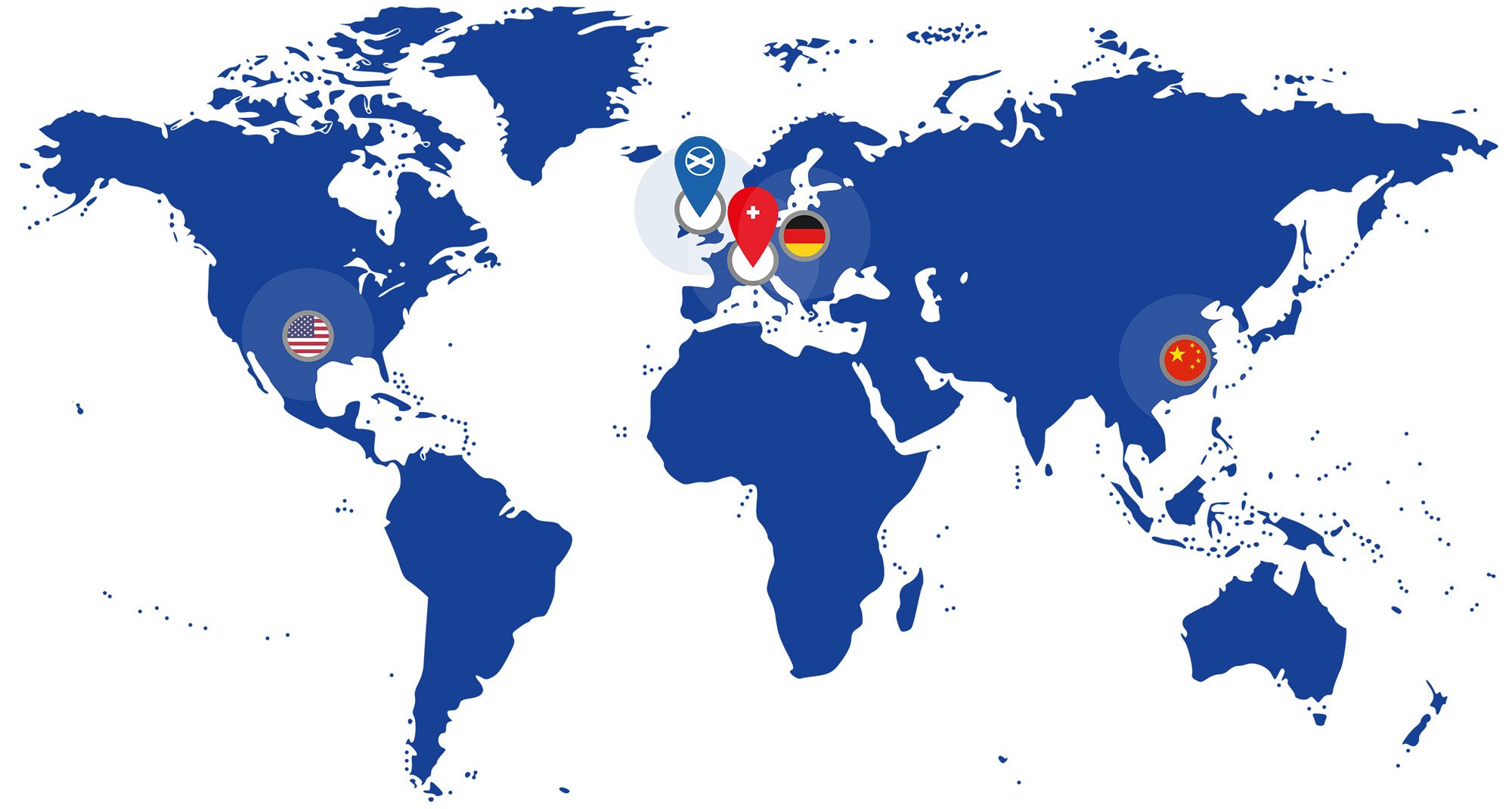

our locations

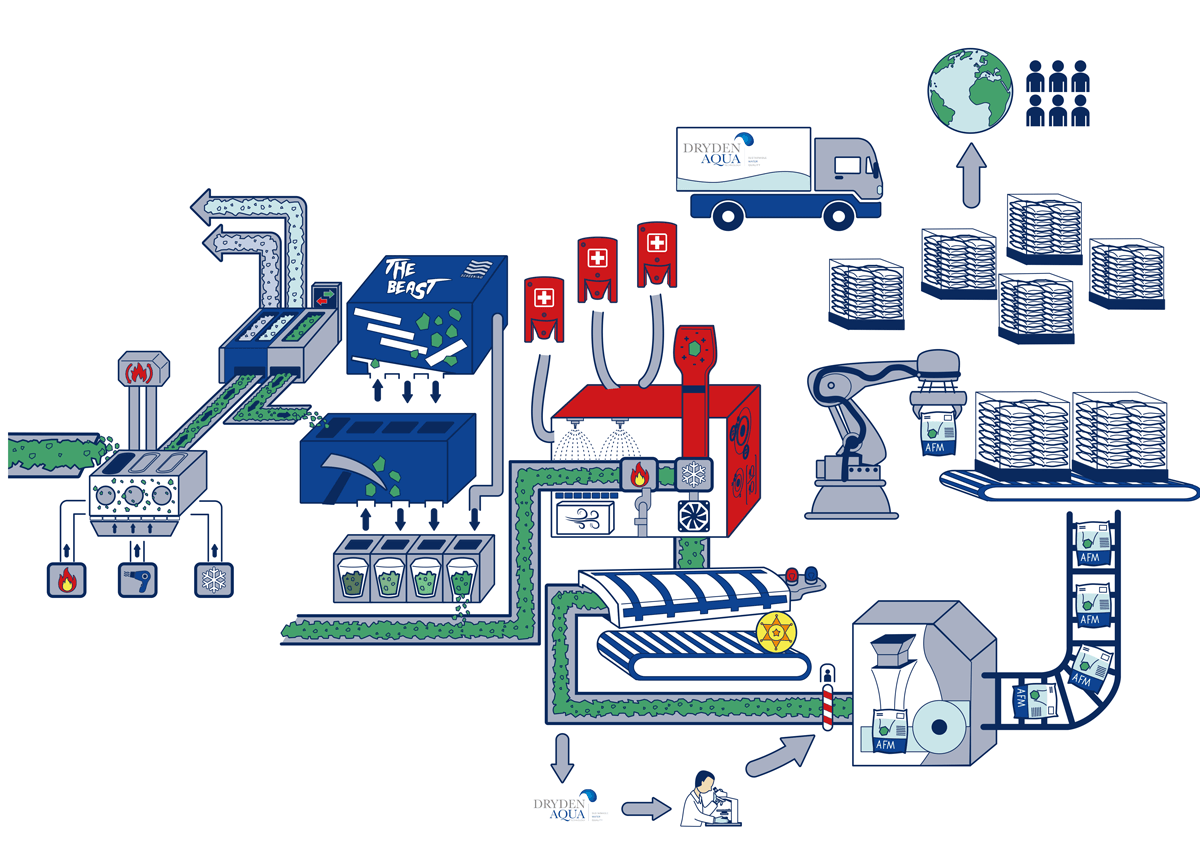

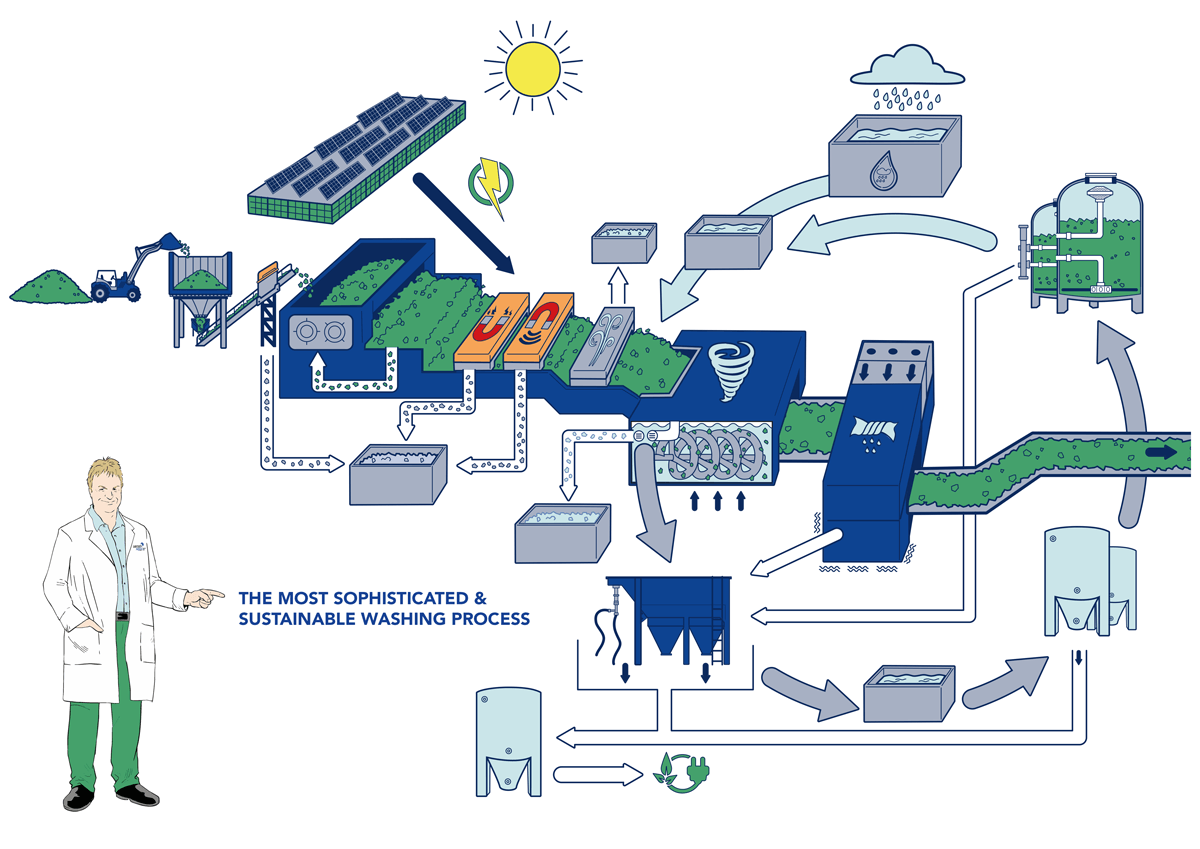

Sophisticated & sustainable glass factory

Our production is probably the most sophisticated glass processing factory in the world. We optimise every part to make the best material available, with the best shape and size for our applications.

AFM® is manufactured under ISO9001-2015 conditions and is certified under DWI EC Reg31, NSF/ANSI 50, NSF/ANSI/CAN 61 by WQA for swimming pools and potable water use and HACCP certified for food and drinks markets.

The recycled glass goes through a first crusher to break oversized pieces

We remove all ferrous and non-ferrous metal pieces using powerful magnets

All papers and plastics are extracted with the use of specific blowers

The glass goes into a unique spiral washer to clean off all impurities

A dewatering screener is used before sending the glass to the dryer

Sustainable:

The rain water we use to wash the glass follows a unique “sustainable loop” at the end of which we can reuse it to wash more glass!

Self-sufficient:

To run our factory, we produce 100% of our own power using solar panels and heat recovery systems.

Zero waste:

The sludge we receive from the washing process is sent to a biogas company and used to produce electricity.

-

The recycled glass goes through a first crusher to break oversized pieces

-

We remove all ferrous and non-ferrous metal pieces using powerful magnets

-

All papers and plastics are extracted with the use of specific blowers

-

The glass goes into a unique spiral washer to clean off all impurities

-

A dewatering screener is used before sending the glass to the dryer

-

Sustainable:

The rain water we use to wash the glass follows a unique “sustainable loop” at the end of which we can reuse it to wash more glass!

-

Self-sufficient:

To run our factory, we produce 100% of our own power using solar panels and heat recovery systems.

-

Zero waste:

The sludge we receive from the washing process is sent to a biogas company and used to produce electricity.

On our new download section

Webdesign by Bönzli + Feuz IT

.jpg)

.jpg)