AFM®

Activated Filter Media

Two different types of AFM® are produced in our factories: AFM®s (standard) and AFM®ng (next generation).

Both products are exposed to a unique 3-step activation process to become self-sterilising and to acquire superior filtration properties. During the activation, the structure and the chemistry of the glass is modified.

1 Self-sterilising surface

2 Increased surface area

3 Advanced adsorption properties

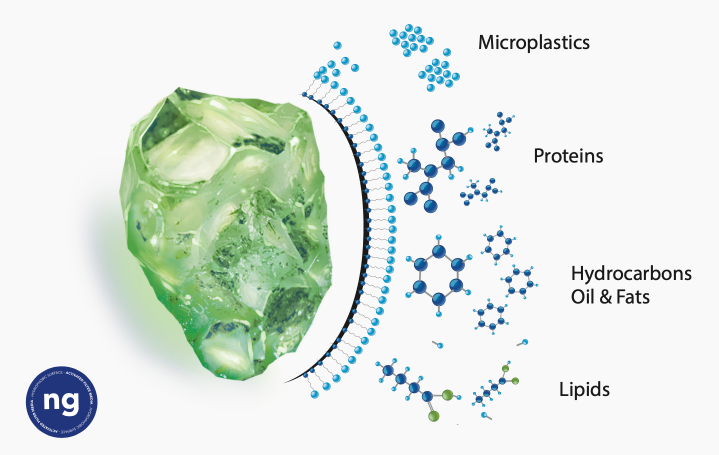

AFM®ng : HYDROPHOBIC SURFACE

Hydrophobic, neutrally charged surface

Superior mechanical filtration performance , combined with efficient removal of hydrophobic contaminants such as hydrocarbons (oil & fats) organics and microplastics in both hard and soft water.

Best filtration performance & organics removal

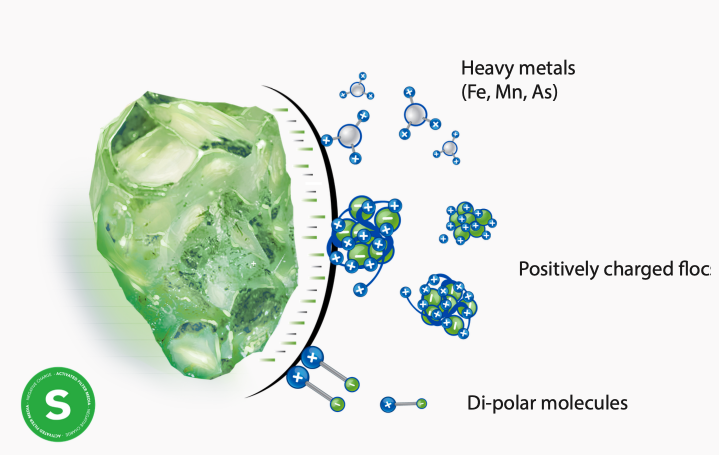

AFM®S: HIGH NEGATIVE SURFACE CHARGE

High negative surface charge

Robust and stable, high filtration performance media with a 20 year track record. Best suited for the removal of positively charged particles such as heavy metals (e.g. Iron, Manganese and Arsenic).

Best for heavy metals removal

Organic matters are the precursor for the formation of Trihalometh- anes (THMs), including chloroform. Thanks to its large hydrophobic area and highly mesopourous structure, AFM® ng can filter much finer particles and approximately 50% more organic substances than sand. High filtration performance means less disinfectants are used, result- ing in healthier water and better air quality at lower costs

2019 IFTS Test results : A certified 1 micron filtration rate without flocculation

On our new download section

Webdesign by Bönzli + Feuz IT