AFM®

Activated Filter Material

What is AFM®?

AFM® Activated Filter Media is a direct replacement for sand, doubling the performance of sand filters without the need of additional investments in infrastructure. AFM® resists biofouling, biocoagulation and transient wormhole channeling of unfiltered water and never needs to be recharged or replaced.

AFM® is a highly engineered product manufactured from a specific glass type, processed to obtain the optimum particle size and shape. It is then exposed to a 3-step activation process to increase its surface area by up to 300 times for superior mechanical and electro-static filtration performance.

The activated surface of AFM® is self-sterilizing which prevents bacteria mud-balling, coagulation and channeling of unfiltered water through the filter bed. Activation increases the surface area by up to 300 times for catalysis and adsorption reactions. Similar to activated carbon, the surface nano-structure adsorbs pollutants from the water but unlike carbon, AFM® is recharged by just back-washing with water.

Your benefits at a glance

- ... more than doubles the performance of an existing filtration system without the need for additional investments

- ... is not subject to biodynamic instability and will never allow untreated water to pass the filter

- ... substantially lowers chlorine oxidation demand by up to 50%

- ... lowers backwash water demand by an average of 50%

- ... is expected to last for the life of the filtration system

- ... provides quick return on investment

AFM® replaces sand in all sand filters

AFM® reduces the biological risk from bacteria and parasites as well as the chemical risk. AFM® does not channel so it is an effective barrier against Cryptosporidium and giardia. AFM® does not incubate or discharge bacteria and will reduce the bacterial load of the product water. Also because of the better filtration performance, there are lower THM concentrations. AFM® also provides an excellent solution to remove metals and heavy metals from water.

AFM® is manufactured in a state-of-the-art hygienic factory designed by Dr. Howard Dryden, CEO and inventor of AFM®. AFM® contains metal oxide catalysts that dissociate oxygen and water to create a zone of high oxidation potential to prevent bacteria growing on the surface of AFM®. In addition, the huge activated surface area has a strong negative charge for the adsorption of sub-micron particles and dissolved organic molecules. This makes AFM® far superior to any other filtration media because AFM® does not need to be replaced and is recharged by a simple back-wash.

What makes AFM® so effective?

Dryden Aqua Intellectual Property protects AFM® but we are happy to share some of the key points;

- We use predominantly green and brown container glass as it has the correct chemical and structural properties for our activation process.

- Particle shape and size distribution are critical for the best fluid hydraulics and solids retention. For example, solids can easily push their way through glass bead filter media but with a subangular AFM® media, the grains lock together to prevent the solids slipping through.

- The AFM® activation process increases the surface area available for adsorption by up to 300 times to 1‘000‘000 m2/m3. This means 300 times more surface area for the adsorption of dissolved organic pollutants. The huge surface area coupled with the magnetic attraction of the negative zeta potential makes AFM® the best filtration media for potable water treatment.

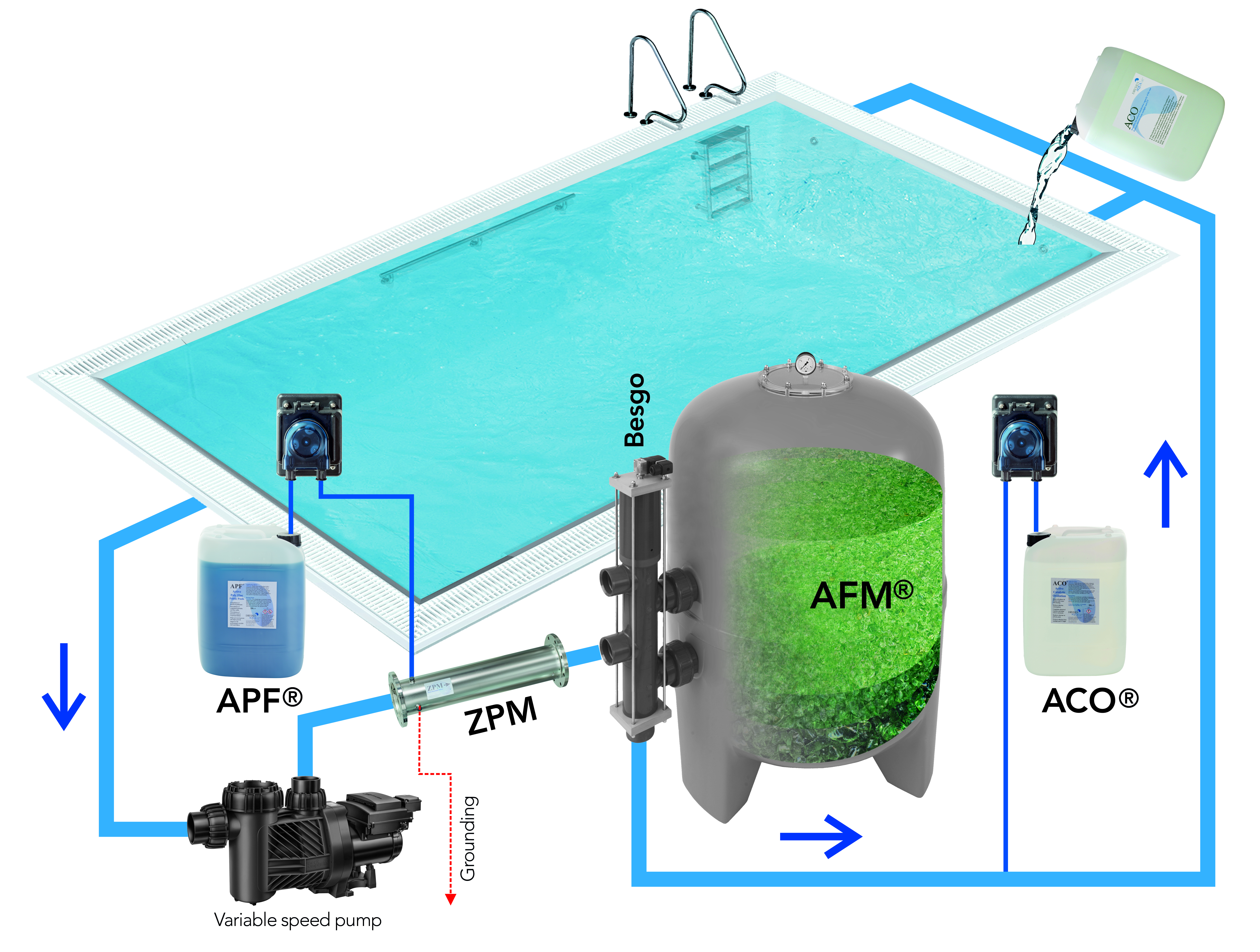

Dryden DAISY® filter circulation for private pools:

Operating criteria

- Filtration velocity: 1 - 30 m/h

- Backwash velocity: 40 - 50 m/h

- Backwash duration: 3 - 10 minutes

- Max. operating differential pressure: 0.5 bar

- Water pH limits: 3 - 9

- Water temperature limits: 1 - 100 C

- For AFM layering details, refer to IFU Instructions for Use Document

AFM® Grade 1 specification

- Bulk bed density: 1‘250 kg/m3

- Effective size: 0.45 mm

- Spherizity: 0.75 - 0.80

- Uniformity coefficient: 1.6 - 1.8

- Aspect ratio: 2 - 2.4

- Specific gravity: 2,4 kg/l

- Organic contamination: < 50g/ton

- Color purity: > 98%

- AFM® is supplied in 21 kg (47 lbs), 25 kg (55 lbs) or 1000kg (2200 lbs) bags

- AFM is available in 4 grades

On our new download section

Webdesign by Bönzli + Feuz IT